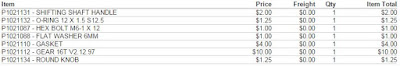

As noted in the prior post it was going to take a few new parts to get my planer up and running with the new Shelix cutterhead. In addition to a replacement "standard" helical gear I also needed a gasket for the gearbox and parts to assemble a new gear shift handle to replace the one that broke during disassembly. After a careful review of the Grizzly G1021 parts diagram I ended up ordering the parts shown below. I was actually somewhat surprised at how reasonable the prices were and the free shipping coupon I received for creating an account didn't hurt either.

Once the parts arrived I dug into rebuilding the gearbox with the hope that the new parts would actually fit and mesh properly. Step one was to scrape off the mating surfaces of the gearbox casing with a razor blade to remove the remnants of the original gasket. Next I reassembled the gear selector handle and the yoke that engages with the moving gear assembly in the left side of the box below. Then I inserted the new cutterhead through the main bearing in the lower right corner. Lacking a press to do this the "right way" I managed to coax it in with a big hammer and a block of wood. Next I was finally able to fit the replacement helical gear and confirm that it fit and meshed properly - WooWhoo! The only hiccup was that the clearance hole for the mounting screw was not quite as deep as the original so I had to run to Fleet Farm and pick up a longer (1") M6 socket head cap screw. One point to note is that I did apply some Loctite "blue" to this screw as well as the screw that attaches the gear selector yoke as loose hardware and gearboxes seem like a recipe for disaster. The image below also shows that the gearbox only has one speed plus a "neutral" as it is missing the alternate gears that would engage with the gear selector handle pushed inward.

Below you can see the gearbox with all the gears in place to get an idea of how everything works together to transfer power from the cutterhead down to the output shaft at the left which then drives the chain gears for additional reduction.

Once the gearbox was buttoned up I moved on to installing the new bearing on the other end of the shaft. This bearing went on easily by using the pulley, a block of wood, and a large hammer as a "poor man's press". I will note hear (in case I forget at some point years down the road) that I did not replace the main bearing inside the gearbox as that required the replacement of an oil seal which I did not think to order ahead of time. With the relatively limited hobby usage this machine will see I am not too concerned but if I have to pull this thing apart again someday to replace the other bearing so be it. At that point I'd probably order a replacement gear set and see if I could get the second speed working.

Re-installing the cutterhead and gearbox was straightforward as outlined in the installation guide and within an hour or so the planer was ready for a test run. I managed to find an oak scrap with some squirrely reversing grain that had suffered some decent tearout when planed with the original cutterhead. After a few passes with the Shelix head it was clear that the tearout was reduced quite a bit although not completely eliminated. It will be very interesting to see just how much this improvement will help reduce the time spent on surface prep during future projects. Despite all the comments from others that have upgraded I was still completely surprised and impressed with the level of noise reduction. I'm not entirely sure that I'll be able to get away with planing while the little ones are sleeping but it quiet enough that I'll have to setup a test run with my wife listening in the house.

Based on first impressions I'm happy with the upgrade and that the hiccups in the installation process were easily resolved. I was impressed with both Holbren and Byrd Tool as they proved that they took customer service seriously and were willing to do whatever it was going to take to get me up and running despite my planer being an odd-ball. At the end of the day I was just happy to get this resolved without the need for any custom machining.

Now I should probably get back to that bed I was building...

Hi This may be an old post but I will try anyway. I bought and auto 15 SA-380 and it is also one speed. Id like to upgrade my gearbox to the dual speed. Do you know if it is possible. Im sure all these planers are built by the same company with different names. So maybe gearbox parts will interchange, I hope.

ReplyDelete